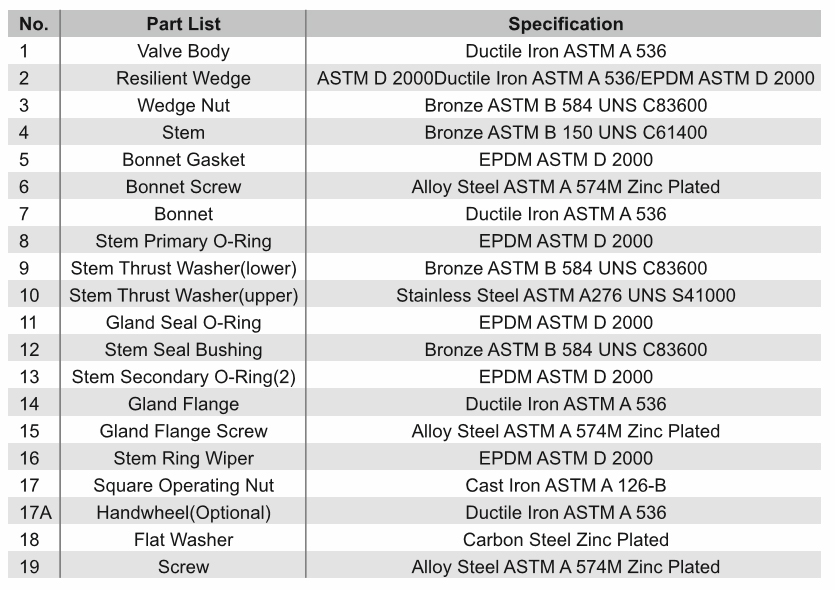

105QS / 108QS

105QS / 108QS Non-rising Stem Groove Joint Ends Resilient Wedge Gate Valves

1 Bolted Bonnet•Non-Rising XGroove•GrooveXGroove 2 250 PSI/300 PSI/17.

2 Bar Non-ShockCoIdWorking Pressure

3 CONFORMSTOAWWA c 509.

4 Coating-Electrostaticallyappliedfuaion-bondedepoxy 0.2-0.5mm.insideand outside.MeetsorexceedsAWWA C550.Maximumoperating temperature 1600071 oc. Freezing Weather Precaution-Subsequent to testing a piping system,valves should be in an open position to allow complete drainage.

S909

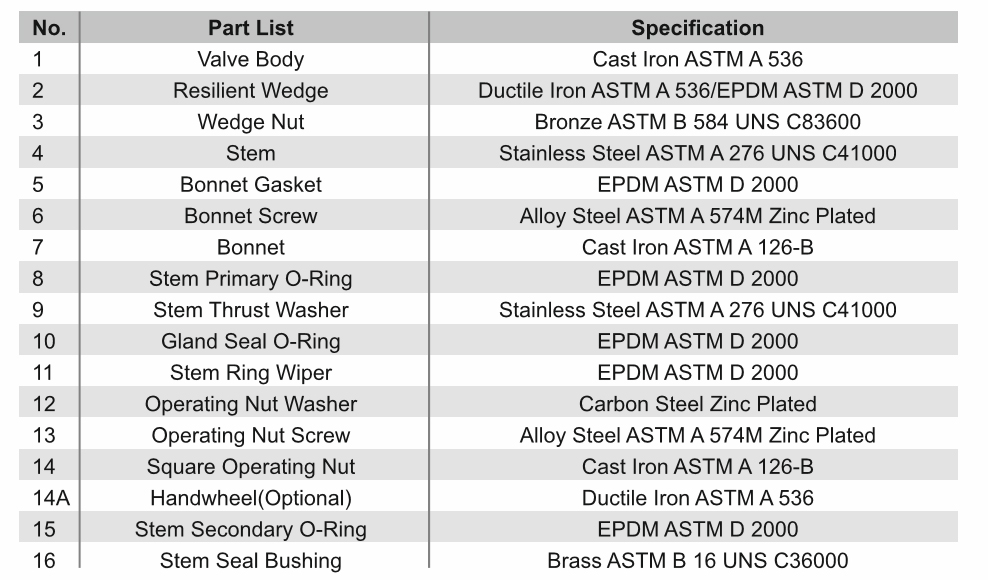

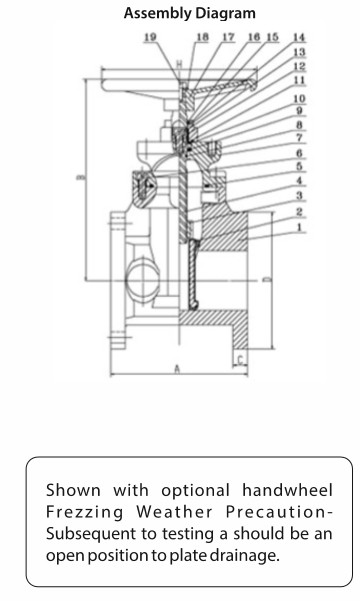

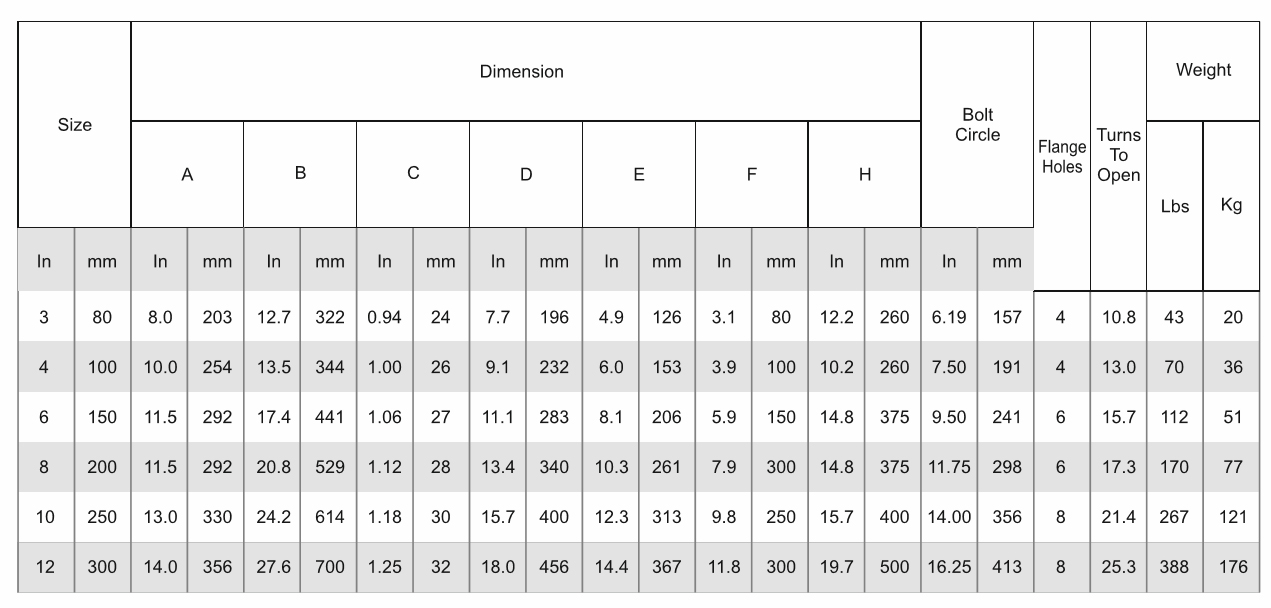

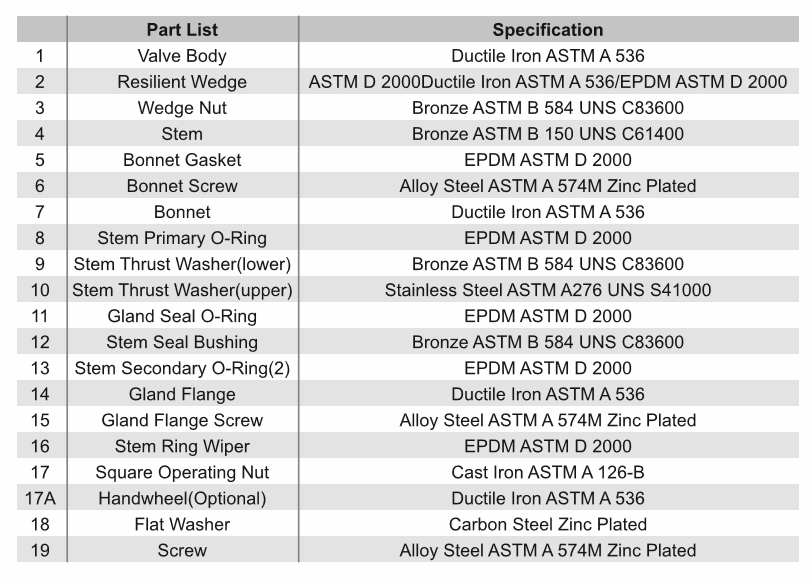

S909 Non-rising Stem Flanged Joint Ends Resilient Wedge Gate Valaves

1 Bolted Bonnet•Non-Rising Stem •ResilientWedge•FIanged Ends

2 250 PSI/300 PSI/17.2 Bar Non-ShockColdWorking Pressure

3 CONFORMSTOAWWA

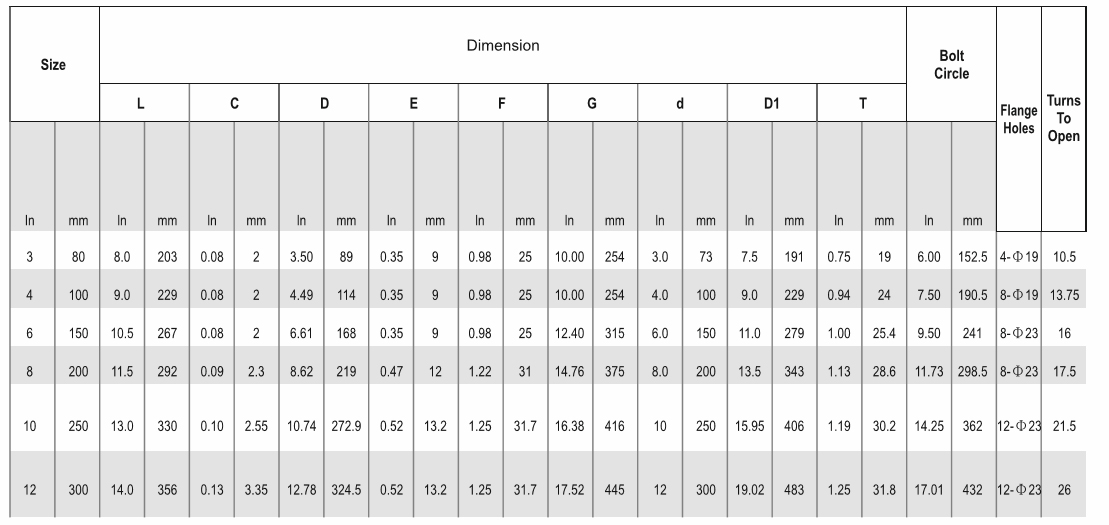

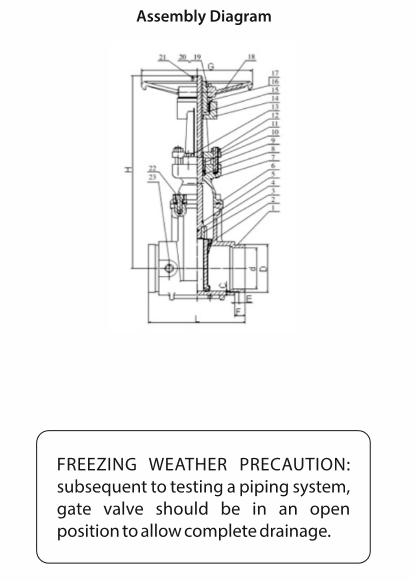

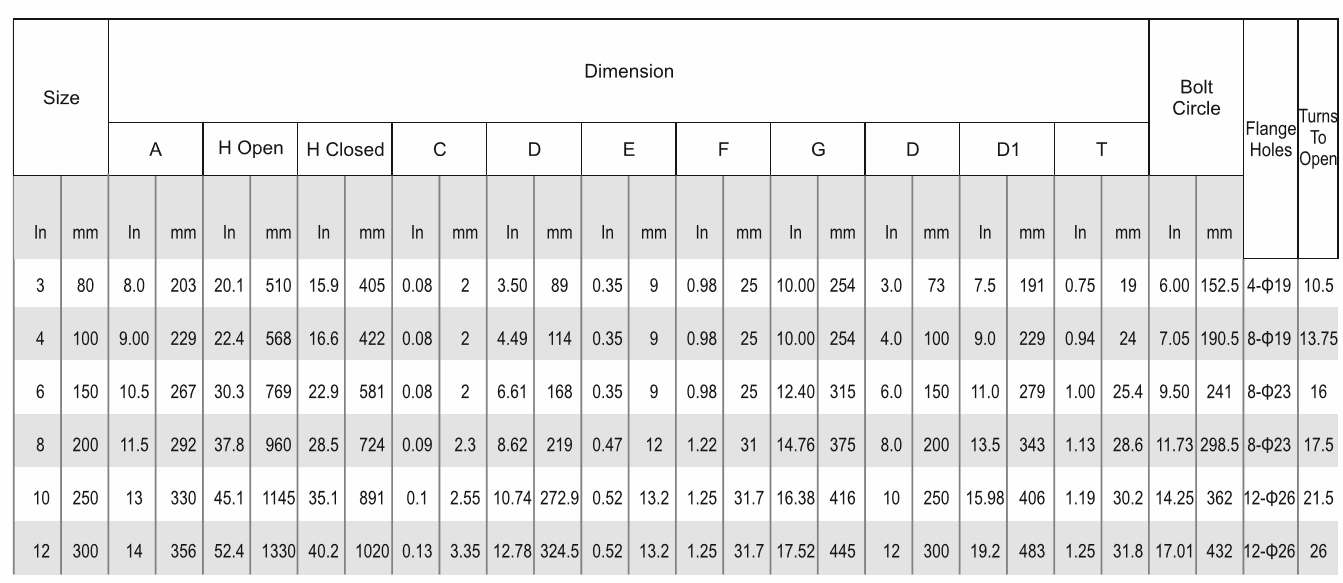

135QS / 138QS

250 PSI AWWA C509 Iron Body Rising Stem Groove Joint Ends Resilient Wedge Gate Valves

1 Bolted Bonnet • Non-Rising Stem • Resilient Wedge • FlangedxGroove • GroovexGroove

2 250 PSI/17.2 Bar Non-Shock Cold Working Pressure 250 PSI/ 17.2 Bar

3 250 PSI/ 17.2 Bar Non-Shock Cold Working Pressure (1600 F/71 0 C max. operating temperature)

4 CONFORMS TOAWWA C509

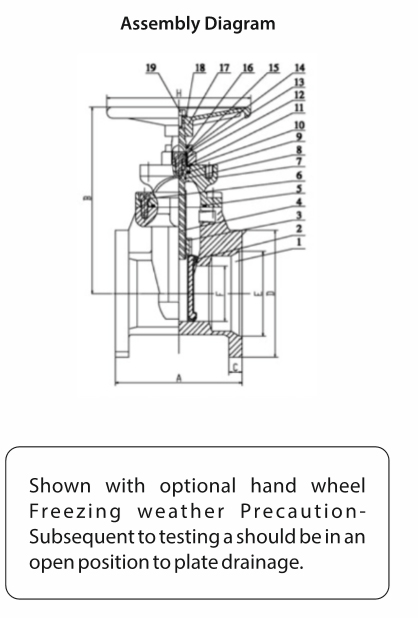

FREEZING WEATHER PRECAUTION: Subsequent to testing a piping system, gate valve should be in an open position to allow complete drainage.

* Electrostatically applied fusion-bonded epoxy coated inside and outside per AWWA C-550

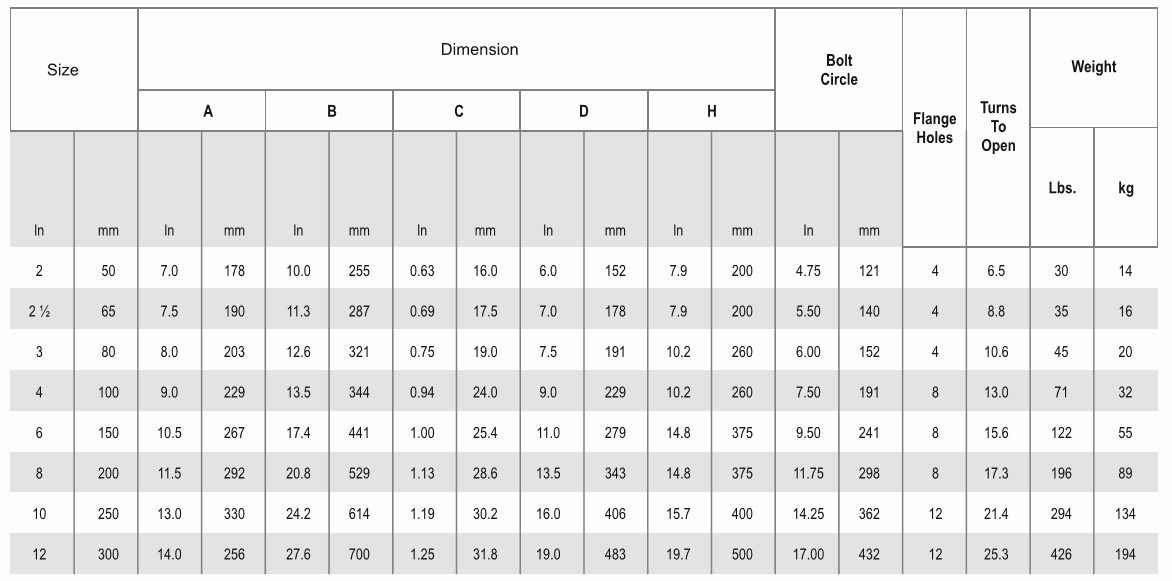

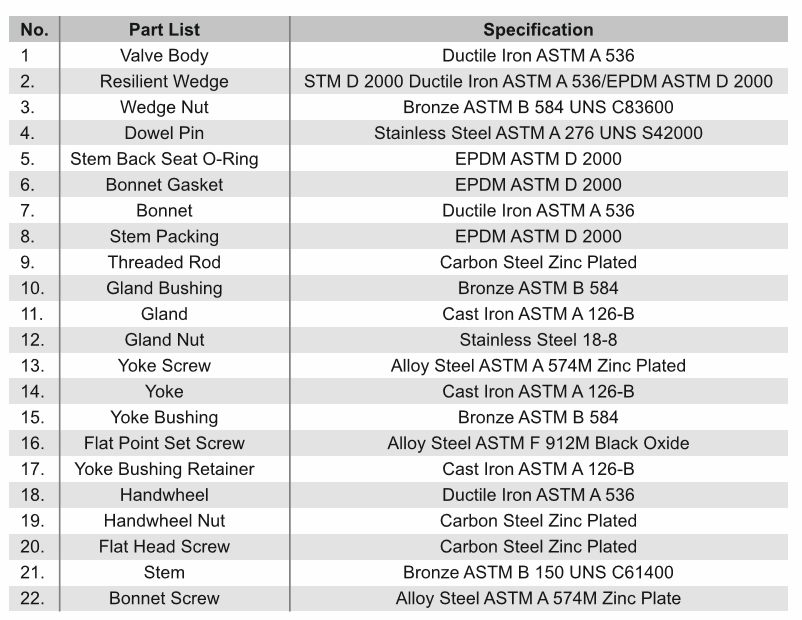

SJ 909

SJ909 Mechanical Joint Ends Resilient Wedge Gate Valves

1 Bolted Bonnet•Non-Rising Stem•ResiIient Wedge•MJ Ends 250 PSI/17.2 Bar

2 250 PSI/300 PSI/1 7.2 Bar Non-Shock cold Working Pressure

3 CONFORMS TO AWWA C509

5 Coating-Electrostatically applied fusion-bonded epoxy 0.2-0.5mm.inside and outside. Meets or exceeds AWWA C550.Maximum operating temperature 1600F/71 oc.

6 Freezing Weather Precaution Subsequent to testing a piping system,valves should be in an open position to allow complete drainage.